Since we started our business at DNT AUTO, we were clear that we weren’t just “just another” player in the sector. We wanted to make a difference with a strong approach: real, innovative technical solutions tailored to the needs of the automotive industry. Today, I can confidently say that we have achieved this.

Textile innovation applied to the automotive industry

Our story begins within DNT Nonwoven Fabrics, a Spanish company with over 30 years of know-how in the nonwovens sector. We specialize in the development and manufacture of technical nonwovens, and we decided to extend this knowledge to the automotive industry with a dedicated unit: DNT AUTO.

At DNT AUTO, we develop high-value technical solutions that optimize nonwoven performance and integrate seamlessly into our customers’ industrial processes. This includes technologies such as laminating, heat sealing, and molding, tailored to the specific functionality and requirements of each application.

What sets us apart in the automotive market

Our advantage lies in proximity, customization, and sustainability.

100% Spanish manufacturing

From our facilities in Alcalá la Real (Jaén), we manufacture all our products with complete traceability and quality control. This not only allows us to reduce delivery times but also maintain a consistent standard of excellence in every batch produced.

Customized technical solutions

Each client has a specific need, and we don’t offer one-size-fits-all solutions. We create custom materials that are lightweight, versatile, and offer specific functional treatments, such as:

- Flame retardants

- Low resistivity antistatics

- Hydrophobic

- Hydrophilic

- UV protection

- Laminates

Real environmental commitment

One of our key pillars is certified quality. It’s not just a promise; it’s a reality endorsed by multiple international standards.

Each of our products is manufactured under protocols that guarantee quality, safety, sustainability, and regulatory compliance.

We reduce emissions. We analyze the life cycle of our products and monitor their carbon footprint.

Real-life applications: where our materials are

Technical covers and seat covers

During logistics and assembly processes, our lightweight and durable technical nonwovens guarantee effective protection against dust, scratches, rain, and oil. They are also easy to apply and offer great versatility in shapes and finishes.

Industrial absorbents

Designed to retain liquids and oils, these nonwoven fabrics are ideal for maintenance environments and industrial areas, where cleanliness and safety are a priority.

Custom interior trim

We optimize vehicle comfort and aesthetics by developing interior trim specifically for each area of the passenger compartment, with weights, colors, and textures adaptable to every need.

Technical packaging

We develop separation and protection materials for automotive components, ensuring their integrity during transport and storage. A crucial solution in an industry where every part counts.

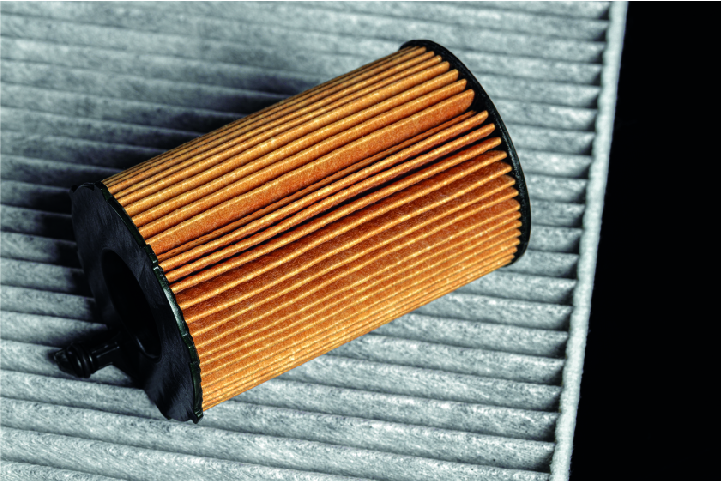

Filters

Our high-performance nonwovens are used in filter manufacturing, ensuring durability, thermal resistance, and excellent mechanical performance.

Being part of SERNAUTO: more than a seal

One of the most successful strategic decisions was joining SERNAUTO, the Spanish Association of Automotive Suppliers. This alliance has allowed us to participate in networking dynamics with other companies in the sector, positioning us as a local, sustainable, agile, and forward-thinking supplier.

A real, sustainable and national alternative

At a time when the automotive industry needs more efficient, lightweight, and sustainable materials, DNT AUTO offers a real European alternative, with local technology, clean production, and a focus on excellence.

Our vision is clear: to lead the development of nonwoven technical solutions for the automotive industry, always in close collaboration with our customers, adding value at every stage of the process, from the idea to the final delivery.